ENGINEERING & CONSTRUCTION

Achieving higher quality enhancement with proven high tech services

At P.U.M. design center, our design team is equipped with state of the art C.A.D. tools to perform technical/structural detailing, calculation of load strength, checking of joint connection, 3D analysis design and detailing of material. All these services add up to higher productivity for P.U.M. customers.

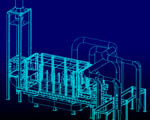

3D Modelling

The structure is created with all the relevant information required for manufacture and construction. The model appears as real elements, with elements having individual geometry, dimensions, member properties, connection types and materials. This ‘true’ 3D modelling approach enable the ease of amendment with instant on-screen display of changes. Thus, the model can be used to simulate actual site condition with more flexibility.

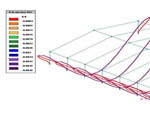

Load Test

Model created can be tested to determine its structural strength prior to erection. The ease of alteration to the original design is achievable by this complementary service.

Nesting

Nesting service provides better material utilisation and shorten the time needed on parts arrangement before fabrication. The material is fully optimised to minimise wastage. In addition, nesting service caters to different purchasing requirements which further enhances the effectiveness of material procurement.

Localisation of Material

The flexibility of changing the elements in the model provides better substitution of alternative materials. The requirement of foreign engineering design can be easily met with materials that are locally available. Thus, time and cost of construction will not be the main factors that restrict implementation of foreign engineering designs.

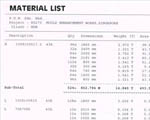

Reports

Reports can be generated to provide better manufacturing management. All the elements of the structure are listed according to individual categories. The lists of beams, columns, joints, bolts ant nuts are classified as required to provide ease of managing.

Comprehensive set of reports

- Material Take-off

- Assembly Part List

- Bolt and Washer List

- Surface Area & Accurate Weight Report

- Centre of Gravity Report

Drawings

Model is finally issued in the following requirements:

- Erection Drawings

- Single Part/ Shop Drawings

- Assembly Drawings

- Drawing in Software Format (I.e. .BMP, JPEG, DWG, DXF and PDF file)

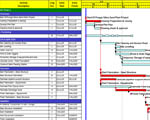

Planning Software

All PUM project are planned using software before execution for submission to client for approval. The schedule will be monitored to deliver the completion as per customers’ requirement for planned start of production.

The planning team also able to do resource planning and cost planning using the software.

ASAHI TECHNO VISION (S) PTE LTD

- 1994

- Supply Workforce For The Construction Of 1 Unit Panel Furnace

- 1996

- Rebuilt One Unit Panel Furnace With All Supporting Additional Structure

- 1999

- Supplied Workforce To Carry Out Hot-Work Repair To Their Furnace

- 2001

- Demolished And Rebuild (Cold Repair) For S2 Furnace Involve The 150mt Steel And 3200 Mt Refractories

- 2001

- Supplied Workforce To Carry Out A Hot-Work Repair To S1 Bowl

BALANCED ENGINEERING CORPORATION (BEC)

- 2007

- Supply Bricklayer For Exxon Mobile Refinery

BINTULU SILICA INDUSTRIES SDN BHD

- 1996

- Supply Workforce For The Construction Of One Unit Sodium Silicate Furnace

- 2002

- Supply Workforce For Brick Patching Of Furnace

- 2004

- Supply Workforce For The Construction Of One Unit Sodium Silicate Furnace

ECC KOREA ENG. CERAMICS CONSTRUCTION

- 2004

- Supply Workforce To Construct 1 Unit Furnace In Gumi, Korea

HAMAY GLASS SDN BHD

- 1997

- Construct One Unit Recuperative With All Supporting Structure And Services To Operate The Furnace. Built 2 Feeder Unit Towards The Forming Machines

- 1999

- Carried Out Glass Draining To Their Furnace With Controlled Cooling Down For Decommissioning

HITACHI CABLE (S’PORE) PTE LTD

- 2001

- Fabricate & Install A Mezzanine Floor Deck Within 1 Week (20mt Steel)

IWAKI GLASS (M) SDN BHD

- 1994

- Supply Workforces To Construct 1 Unit Gas Melting Furnace

- 1998

- Demolished And Rebuilt 1 Unit Melting Furnace And Constructed The Furnace Platform

- 2001

- Demolished And Rebuilt Mg2 Melting Furnace And Constructed The Platform Extension

- 2002

- Demolished And Rebuilt Mg1 Melting Furnace And Constructed The Platform Extension

- 2003

- Demolished And Rebuilt Mg2 Melting Furnace

JASA SYNTEX ENGINEERING SDN BHD

- 2002

- Supply Workforce To Repair Refractory Lining For 1 Unit Chimney At Pasir Gudang

- 2003

- Supply Workforce To Repair Refractory Lining For 1 Unit Of Chimney At Kapar

JG CONTAINERS (M) SDN BHD

- 2002

- Demolished And Rebuild (Cold Repair) For A New Design Furnace; Rebuild The Existing Chimney With Extension.

KL GLASS MANUFACTURERS CO. SDN BHD

- 1992

- Supply Workforces Under Engineers Of Aci To Construct One Unit Distribution Channels And One Unit Of Feeder For The Existing Furnace

- 1994

- Hot-Work Repair To The Existing Furnace. Supply Workforce Under Aci To Cold-Repair One Unit Of Furnace

- 1997

- Carried Out Cold Repair To Their Two Furnaces Concurrently

- 1998

- Demolished And Rebuilt One Unit Of End Fired Furnace, With Increase Capacity, All Supporting Steel Structures And Auxiliary Services To Operate The Furnace

- 2001

- K23 Project – Fabricate & Installed 1 Unit Of Steel Casing And Refractory Work.

- 2003

- K23 Project – Dismantle And Relocate Machinery Works

MALAYA GLASS PRODUCTS SDN BHD

- 1987

-

- One Unit End Fire Furnace

- 2 Feeder Units Towards Forming Machines

- 1988

-

- One Unit End Fire Furnace With All Supporting Structures And Services

- 2 Feeder Units Towards Forming Machines

- 1990

-

- Demolished And Rebuilt One Unit End Fire Furnace

- 3 Feeder Units Towards Forming Machines

- 1994

- Demolished And Rebuilt One Unit Feeder And All Supporting Structures

- 1996

-

- Demolished And Rebuilt One Unit End Fire Furnace

- 2 Feeder Units Towards Forming Machines

- 1998

-

- Demolished And Rebuilt One Unit End Fire Furnace

- 2 Feeder Units Towards Forming Machines

- Design And Construct The Supporting Hearth Platform

- Designed And Constructed One Unit Glass Cullet Scraper Conveyor.

- 2000

- Carried Out Hot-Work Repair On Supporting Hearths Of Existing Furnace

- 2001

-

- Carried Out Hot-Work Repair On Breast Wall Of Furnace (M1)

- Checker Replacement Hot Work Of Furnace (M2)

- 2002

- M3 Diffuser Extension

- 2003

- Construct One Unit Fore Hearth With All Supporting Platform And Ducting (Is9-M3)

- 2004

- Demolish And Rebuilt One Unit End Fire Furnace Including Air Ducting And Chimney. Built 2 Feeder Units Towards The Forming Machines

- 2007

- Demolish And Rebuilt Furnace (M1)

MALAYSIAN SHEET GLASS BHD

- 1992

-

- Supply Workforces For Construction One Unit Float Glass Furnace (Jbif)

- Construct Refractory Lining Of A Chimney

- 1997

-

- Supply Workforces For The Construction One Unit Glass Furnace (Jb2f)

- Construct Refractory Lining Of One Unit Of Chimney

- 1997

- Construct Refractory Lining Of One Unit Of Chimney

- 2001

- Cold Repair On Existing Jb2f Float Glass Furnace

- 2005

- Cold Repair On Existing Jb1f Float Glass Furnace

MALAYSIAN UNITED CHEMICAL CORPORATION SDN BHD

- 1992

- Supply Workforces For Construction One Unit Sodium Silicate Furnace

- 1993

- Supply Workforces And Supervised The Draining And Controlled Cooling Down Of Sodium Silicate Furnace

- 2001

- Hot Repair On The Doghouse Sidewall

- 2002

- Supply Workforces And Supervised The Draining And Controlled Cooling Down Of Sodium Silicate Furnace

MALAYA VIETNAM GLASS LIMITED

- 2004

-

- Demolish And Rebuilt One Unit End Fire Furnace Including Chimney.

- Built 3 Feeder Units Towards The Forming Machines In Ho Chi Minh, Vietnam

NH TECHNO VISION (S’PORE) PTE LTD

- 2001

- Supply Workforce To Construct 1 Unit Furnace

- 2002

-

- Supply Workforce To Construct 1 Unit Furnace

- Supply Workforce To Rebuild 1unit Furnace

- 2003

- Supply Workforce To Repair 1 Unit Furnace

- 2004

- Supply Workforce To Repair 1 Unit Furnace

- 2005

- Supply Workforce To Repair 1 Unit Furnace

- 2006

- Supply Workforce To Rebuilt Lcd Furnace

- 2007

-

- Supply Workforce To Carried Out Hot-Work To Repair Furnace

- Supply Workforce To Repair Furnace

POLYGLASS FIBRE (M) SDN BHD

- 1992

- Supply Workforce And Supervision For The Construction Of One Unit Fiberglass Feeder

- 1994

- Carried Out A Hot-Work Repair To The Existing Furnace

- 1997

- Cold Repair One Unit of Fibre Glass Feeder

- 2007

- Forehearth Repair

SAMSUNG CORNING (M) SDN BHD

- 1994-1995

- Construct One Unit Funnel Furnace And One Unit Panel Furnace For Tv Tube With All Supporting Structures. Also Construct Refractory Lining For 2 Units Of Chimney

- 1996

- Constructed 2 Feeder Units, Each To Every Furnace With Supporting Structures

- 1998

- Carried Out Bowl Change To One Of Their Feeders

- 1999

- Constructed The Steel Structure And Panelling Of Ctv Pin Removal Plant (200mt Steel); Carried Out Hot-Work Checker Repair To Their M2 Furnace Regenerators.

- 2001

- Fabricated & Installed 2 Units Of Overflow Casing And Refractories Work.

- 2002

- Fabricated 7 Installed 1 Unit Of A Vendor Workshop Steel Structure

- 2003

- M1 & M2 Port And Melter Crown Hot Repair

- 2004

-

- Carried Out Hot Checker Replacement

- Constructed The Steel Structure And Panelling Of Ctv Pin Removal Plant (200mt Steel); Carried Out Hot-Work Checker Repair To Their M1 Furnace Regenerators.

SEE SEN CHEMICAL BHD.

- 2002

- Demolished And Rebuild The Refractory Lining For 1 Unit Of Acid Converter

- 2004

- Demolished And Rebuild The Refractory Lining For 1 Unit Of Acid Converter

SOUTH PACIFIC CHEMICAL INDUSTRIES (SPCI)

- 2007

- Furnace Repair

TAIWAN NH TECHNO GLASS CORPORATION

- 2003 & 2004

- Supply Workforce To Construct 1 Unit Furnace In Taiwan

ASTA-NAZ SDN BHD

- 2001

- FABRICATE & INSTALL 40mt ROOF TRUSSES FOR LLM KAJANG MULTIPURPOSE HALL

INAI KIARA SDN BHD

- 2007

- OLD PUTRA ASSOCIATION (OPA) OFFICE BUILDNG (OFFICE EXTENSION)

JR MARINE

KONE CRANE REPAIR – JOHOR PORT

PERNIAGAAN USAHASAMA MEMBALAK SDN BHD

- 2003

- WARE HOUSE CLADDING

UZAIMIN ENTERPRISE

- 2000

-

- CONSTRUCTED ONE UNIT ADMINISTRATION BLOCK, STEEL DECK AND PAINTING WORK FOR SEKOLAH DATUK ABDUL RAZAK, SEREMBAN (SDAR)

- CONSTRUCTED ONE UNIT OF LOWER ROOF FOR THE ADMINISTRATION BLOCK OF SDAR

- 2001

- CONSTRUCTED 2 UNITS OF ENTRANCE PORCH FOR THE ACADEMIC BLOCK OF SDAR

ENGINEERING DRAWING & DETAILING SERVICES

- W.E. ENGINEERING SDN BHD

- DRAWING DETAILING FOR PROJECTS INCLUSIVE TNB JAMANANJUNG FUEL POWER PLANT, OIL PUMP HOUSE, GAS STORAGE, PERLIS POWER PLANT.

- YEE LONG ENGINEERING

- WHAFT CRANE MAT

- SRI PELAGAT SDN BHD

- PUTRAJAYA SPIRAL STAIRCASE

- LEIGHTON

- CAT LADDER

- EMENEA ENGINEERING

- TECHNOLOGY PARK